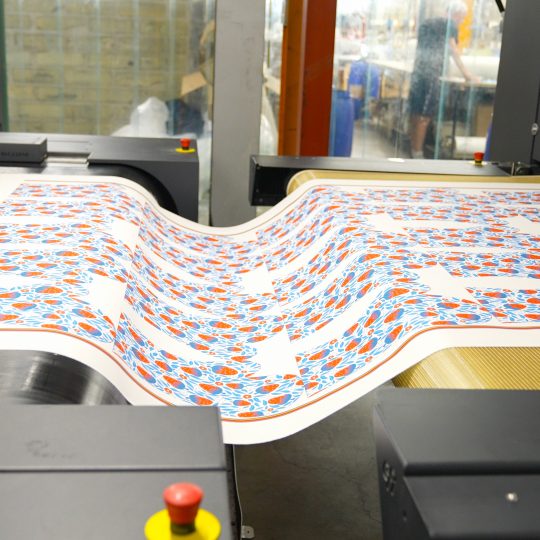

Efi Reggiani Power Reactive Digital Printer

The Reggiani Power printer is a 32 head printer which specializes in speed, it has the capacity to print 360 metres per hour. We chose this machine because it means we are able to have the capacity to take on more orders, get them printed quicker but still be able to maintain a high quality print. Click to watch a video of the machine in action! It has 8 colours: cyan, magenta, yellow, black, orange, red , grey and blue and each head has a DPI of 600 res. This machine is not only incredibly fast, it has a wide colour range and a fantastic print quality. Click to watch the machine in action!

Order Printed Fabric

Order Printed Fabric  Tea Towels

Tea Towels  Cushions

Cushions  Oven Gloves

Oven Gloves  Adult Aprons

Adult Aprons  Child Aprons

Child Aprons  Tote Bags (Boxed Bottom)

Tote Bags (Boxed Bottom)  Tote Bags (Flat Bottom)

Tote Bags (Flat Bottom)  Washbags

Washbags  Premium Washbags

Premium Washbags